Home > Dispensing Robot

Selective Coating Machine, CWCC-6

Application:

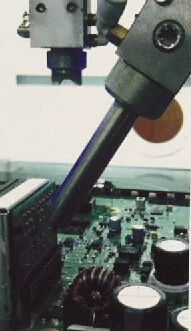

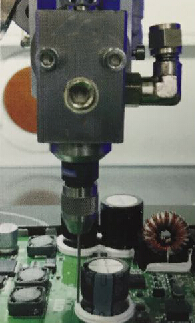

PCBA surface coating, dam process, coating solder mask, DIP components fixing.

Features:

1.Motion controller use computer+,WINDOWS operating system, failure alarming menu

2.Available by manual teaching programming which is easy and quick

3.Integral steel moving platform, to ensure the smooth running

4.X, Y, Z three-axis motion

5.Servo motor+ball screw drive

6.Run precision of 0.02mm,automatically eliminate difference

7.Nozzles automatic cleaning device

8.Special aluminum alloy rail and stainless steel conveyor chain

9.Independent material container

10.Equip with gas collection, exhausting devices

11.SMEMA port to connect with other devices

Technical parameter

|

Model |

CWCC-6 |

|

External Size L*W *H |

900*1280*1630mm(L*W*H) |

|

Weight |

700KG |

|

Control Mode |

IPC+control card |

|

Software |

CW software+Windows |

|

Programming |

Teaching box |

|

Axis |

X、Y、Z |

|

Drive |

Servo motor +ball screw |

|

Max. move speed |

1000mm/s |

|

Coating scope |

L460*W460mm |

|

Max .PCB height |

up 100 down 100mm |

|

Rotation angle |

±180º |

|

Positioning accuracy |

0.02mm |

|

Repeat accuracy |

0.02mm |

|

Conveyor quantity |

1 |

|

Width adjusting mode |

auto |

|

Width adjust speed |

250mm/min |

|

Conveyor height |

900±20mm |

|

Conveyor speed |

2-5mm/min |

|

Conveyor direction |

L-R(R-L optional) |

|

PCB edge space |

≧3mm |

|

Conveyor motor power |

DC24V 69W |

|

Communication port |

SMEMA port |

|

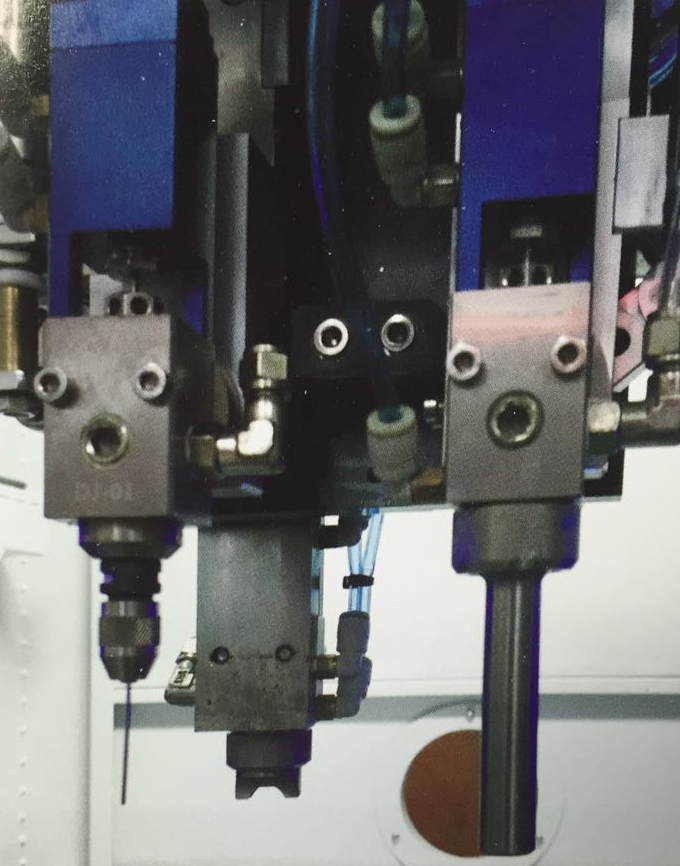

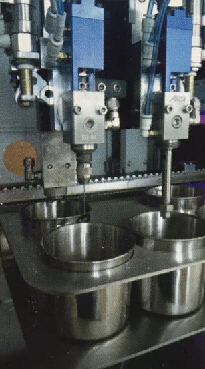

Nozzle quantity |

2 sets |

|

Nozzle type |

pin type spray nozzle,film nozzle |

|

Tilt angle |

0~35º |

|

Single coating width |

2~10/2-30mm(According to the selected value) |

|

Material volume |

5L |

|

Draft capacity |

15 m3 /min |

|

Power supply |

AC220V 50/60Hz |

|

Total power |

2.6KW |

|

Pressure |

0.6Mpa |

|

Programming panel |

Standard |

|

Material Detection |

Standard |

|

Camera location |

Standard |

|

Clamp device |

Standard |

|

Bar code |

Standard |

|

UPS |

Standard |

|

Waste recycling |

Standard |

Nozzle option and function:

|

|

|

|

|

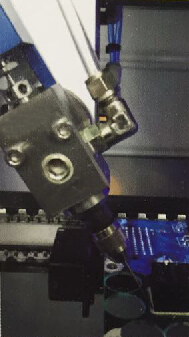

Tilt for dispensing |

Tilt for coating |

|

|

|

|

|

|

Can equipped with 2 sets of nozzle. It can choose 3 from 5 that SA-W5, SA-W3,DJ-01, LA-W30, SC-W10 2 of them can be 35° tilt to achieve 5 axis working. The nozzle can down 75mm, and 3 nozzles can switch crbitrarily. The whole holder can be 360° rotation which can make high efficiency accuracy no-deadcorner. |

Big area coating |

Components fixing, Dam protecting, Dot seal glue |

|

|

|

|

|

Automatic purging when waiting |

Automatic solbent after purging |

Contact: Bunny

Phone: /Wechat/Whatapp: + 86 136 8490 4990

Tel: 0769-82784046/86-13684904990

Email: s4@smtfly.com

Add: Building 2, Gang Hua Xing Industrial Park, Chongqing Road, Fuyong Town, Shenzhen, China 518103