Home > Laser Soldering

Optional Automatic Vision Laser Soldering,SmtflyLS-V Special Features:

1.saving tin for transiting tin with a certain quality No need to change tin wire.

2.There is no need to add prefluxing, without full heating, low energy consumption, the perfect solution to surface warping problem.

3.Suitable for large and small size, less solder joints, solder joints are difficult to approach, the inner layer of high difficulty products.

4.Top delivery tin and bottom delivery tin two kinds of models, optional from top to top welding, no need to turn plate, solve labor cost and fixture complex problem.

5. Efficient heat application and solder supply enables stable soldering automation.

6. It enables soldering in narrow confines on high-density board assembly.

7. High maintainability.

Product Description

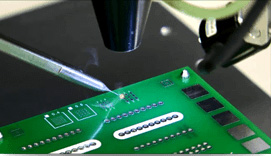

The product flows from the track into the welding station. After CCD photography, the tin wire drawing mechanism sends the tin wire to the site to be welded, and the laser laser tin completes the welding.

Laser soldering robot

The technology makes possible automation where previously not practical.

Technology is evolving quickly. Mainstream is no longer applicable as evidenced by the emergence of ultrafine electronic circuit boards and multi-layered electrical components. Laser makes possible ultrafine area and other types of soldering that are difficult using tip soldering, which drives enormous advantages. Before adoption of new technology, read laser soldering method to understand differences from contact soldering method.

Parameters:

Subject

Technical Parameters

Name

Laser Top Layer Soldering System

Power Interface

2P 220V 50HZ

Laser Power

60W

Spot Size

0.3mm

Wave Length

808nm

Positioning Way

CCD

Temperature Monitors

Infrared temperature measurement (coaxial temperature measurement)

Work Range

300mm*300mm

Total Power

2kw

Size

1200*1200*1700

Weight

180kg

Application

1.Widely used in aerospace, military industry, automotive electronic industry and other industries

|

|

|

|

|

|

|

|

|

|

Exposure position marks (Line Type )

|

Exposure position marks (Square Type )

|

2.Our extensive experience in systems introductions has let us establish application knowledge for laser soldering. We guarantee that customers can adopt these systems with confidence.

However, laser soldering is absolutely not just a replacement for contact soldering. It is important to distinguish the strong points of each and match them to the application.

Contact: Bunny

Phone: /Wechat/Whatapp: + 86 136 8490 4990

Tel: 0769-82784046/86-13684904990

Email: s4@smtfly.com

Add: Building 2, Gang Hua Xing Industrial Park, Chongqing Road, Fuyong Town, Shenzhen, China 518103