Home > SMT Pick and Place Machine

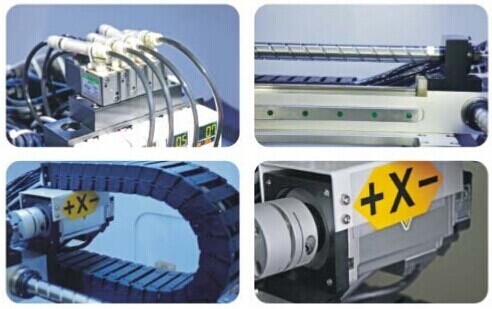

1) The platform transmission uses the imported linear guide rail and lead screw in combination with theJapanoriginal Panasonic servo drive ensuring the high-speed stationarity and control precision of the platform.

2) The transmission of the X and Y shafts uses the imported high-precision ground lead screws and linear guide rails in combination with the Japan Panasonic servo drive ensuring the high precision and high speed of mounting.

3) 4 sets of high-speed mounting heads work simultaneously. The sucking heads use high-precision durable spline shafts.

4) Easy operational program, much more convenient, automatic vision makes position fixing more accurate and convenient.

5) Multi Feeder optional, can meet different kinds of LED mounting.

6) Powerful software adopts numbers and images to display the program coordinate, easy and more convenient.

7) Software adopts data system, and store different types of PCB for convenient adjustment, just need to programming one time for new products to use forever.

8) Platform: Y axis, X axis can be moved manually, speed adjustable, can achieve arbitrary point manual arrived, convenient programming.

9) LED Pick & Place Machine use imported vacuum detection system, it can check the suction accurately to prevent material leakage and throwing effectively.

10) Internal negative pressure system: low noise, long service life and vacuum pressure constant.

11) Standard setting:1 PC,4 mounting heads,12 nozzles.

12) Optinal :8mm,12mm,16mm 24mm automatic feeder, different nozzles, industrial pump, air compressor .

|

Model |

CWTP-4H |

|

Max circuit board size |

1200×300mm |

|

Max moving range |

X axis 1210mm, Y axis 330mm |

|

Max moving range of Z axis |

10mm |

|

Typical Mounting speed |

20000cph |

|

Max mount speed |

28000cph |

|

Mount accuracy |

±0.05mm |

|

Position method |

Visual position |

|

Component available |

0603and above SMD component and LED |

|

Programme method |

Automatic data import/ video study/ keyboard input |

|

Belt feeder |

8mm, 12mm, 16mm and 24mm(OPT) |

|

suction nozzle |

JKUI suction nozzle504、505 & 506 |

|

Operation system |

WINDOWS XP |

|

Compressed air |

Vacuum air in machine |

|

Power supply |

220V,50Hz, 1.2Kw |

|

Weight |

750Kg |

|

Dimension |

2000MM(L)*930MM(W)*1450MM(H) |

Contact: Bunny

Phone: /Wechat/Whatapp: + 86 136 8490 4990

Tel: 0769-82784046/86-13684904990

Email: s4@smtfly.com

Add: Building 2, Gang Hua Xing Industrial Park, Chongqing Road, Fuyong Town, Shenzhen, China 518103